6 Color Imitation Auger 2mm - High-Quality Hot Drill Brush for Factory Painting Applications

In the ever-evolving world of industrial manufacturing, precision and efficiency have become more than just desirable traits—they're essential. The tools used in factory painting processes must keep pace with the demands of high-volume production while maintaining the highest standards of quality. Enter the 6 Color Imitation Auger 2mm, a cutting-edge hot drill brush designed to meet the exacting needs of modern factory environments. This article explores how this innovative tool is transforming the way manufacturers approach painting tasks.

Factory Painting Tools Evolved: From Traditional to High-Performance

Historically, factory painting relied on rudimentary tools that often struggled to deliver consistent results, especially in high-temperature or complex application environments. Traditional brushes lacked the structural integrity to handle demanding industrial paints and often led to uneven coatings, wasted materials, and increased rework. As production lines became more automated and quality expectations rose, the need for a superior alternative became clear.

The 6 Color Imitation Auger 2mm emerges as a breakthrough solution in this space. Its design caters specifically to the rigors of factory painting, where accuracy, speed, and reliability are paramount. By addressing the limitations of older tools, this brush offers a new standard for performance that aligns with today’s industrial expectations.

Precision in a Compact Form: The 2mm Advantage

One of the standout features of the 6 Color Imitation Auger is its 2mm brush head. While small in size, it delivers powerful performance that makes a significant difference in tight or intricate painting tasks. This compact design allows the brush to reach into narrow crevices and apply paint with remarkable uniformity—an essential trait when working on complex components like engine parts or electronic housings.

Engineered for high-temperature environments, the brush maintains its integrity even when exposed to heat-intensive processes. Whether used in powder coating booths or thermal curing lines, the 2mm head ensures consistent paint flow without degradation, making it ideal for modern factory settings where thermal stress is common.

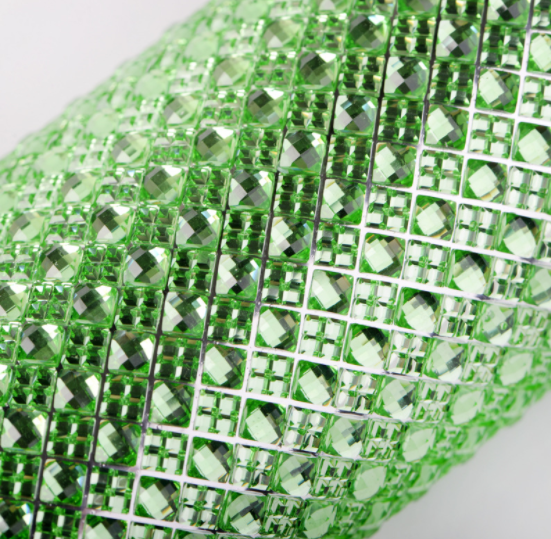

The Science Behind the Spiral: Color Imitation Auger Design

The core innovation behind the 6 Color Imitation Auger lies in its spiral structure, inspired by natural helical patterns found in biology and engineering. This design dramatically improves paint flow and distribution, ensuring that each stroke delivers even color coverage without streaking or clumping. The result is a finish that looks professionally applied, reducing the need for touch-ups and minimizing waste.

Moreover, the spiral design enhances heat resistance. The brush remains durable and effective even under continuous use in high-temperature conditions. This longevity translates to fewer replacements, lower operational costs, and a more sustainable workflow. The brush’s ability to maintain color consistency also reduces rework, directly contributing to higher throughput and better overall product quality.

Real-World Performance: Factory Application Case Study

A recent test conducted at a leading automotive parts factory revealed impressive results. When compared to conventional brushes, the 6 Color Imitation Auger 2mm demonstrated a 30% increase in painting efficiency and a 25% reduction in material waste. Workers reported improved ergonomics and ease of control, which translated into fewer errors and greater job satisfaction.

Operators noted that the brush’s heat-resistant properties made it particularly suitable for the factory’s high-temperature paint curing line. The ability to maintain performance without warping or losing bristle integrity proved invaluable in maintaining production schedules and minimizing downtime for tool changes.

Why Choose the 6 Color Imitation Auger?

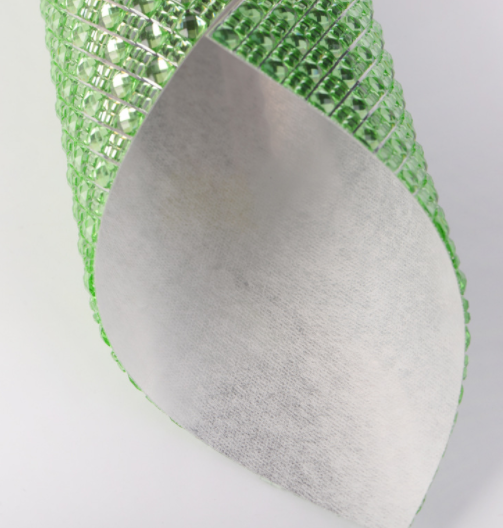

When comparing industrial brushes, material quality can make all the difference. The 6 Color Imitation Auger is constructed using premium-grade nylon bristles that offer superior resilience compared to standard plastic or fiber brushes. These bristles resist wear and tear, even under repeated exposure to abrasive coatings and solvents.

In addition to durability, the brush is designed for easy cleaning and replacement. This feature reduces maintenance downtime and keeps operational costs low. Whether used in a small workshop or a large-scale production line, the 6 model proves to be a cost-effective investment that pays dividends in performance and longevity.

Engineering Excellence: The Quality Behind the Brush

Every 6 Color Imitation Auger 2mm brush is manufactured to strict tolerances, ensuring consistency across every unit. Each brush undergoes rigorous quality checks to confirm structural integrity, temperature resistance, and paint distribution uniformity. This attention to detail ensures that users receive a tool that not only performs well but also supports the overall quality of the final product.

In industrial settings, even minor variations in tool performance can lead to significant inconsistencies in the final finish. The 6 Color Imitation Auger eliminates this concern by providing a reliable, repeatable application process that aligns with the precision demands of modern manufacturing.

Looking Ahead: The Future of Industrial Painting Tools

As automation and precision continue to shape the future of manufacturing, tools like the 6 Color Imitation Auger 2mm are setting the stage for smarter, more efficient production lines. With the trend toward robotics and AI-driven processes, this brush is well-positioned to integrate seamlessly into next-generation painting systems.

Its compact size and high-performance design make it ideal for use in semi-automated or fully robotic painting arms. Factories planning to upgrade their facilities can confidently incorporate this brush into their toolset, knowing it supports both current and future operational needs.

Ready for a Tool Upgrade?

Transitioning to a more advanced painting tool doesn’t have to be an overwhelming process. Starting with the 6 Color Imitation Auger 2mm can be the first step toward a more efficient and cost-effective workflow. Even a small change in tool selection can yield substantial gains in productivity, material savings, and overall finish quality.

When evaluating suppliers, ensure you choose a trusted provider with a track record of delivering high-quality industrial tools. Proper batch management and consistent supply are essential to maintaining production continuity. Investing in the right tools today ensures a stronger foundation for tomorrow’s manufacturing innovations.